Optimized Tooling Design for Rotor Manufacturing

At Rotor Design Solutions, we design rotor profiles with tooling efficiency built in. From the outset, each rotor is engineered to support larger tool radii—extending tool life, reducing manufacturing costs, and delivering exceptional precision in every component.

Advanced tooling design

We provide advanced tooling design solutions for:

- Disk tools for milling and grinding

- End mills for complex profile machining

- Fly tools for worm wheels

- Hobs for rotors and gear components

Designing cutting tools for helical rotors is a sophisticated challenge. While zero helix angle rotors allow for a direct tool-to-profile match, increasing the helix angle introduces complex geometry that requires a highly calculated approach.

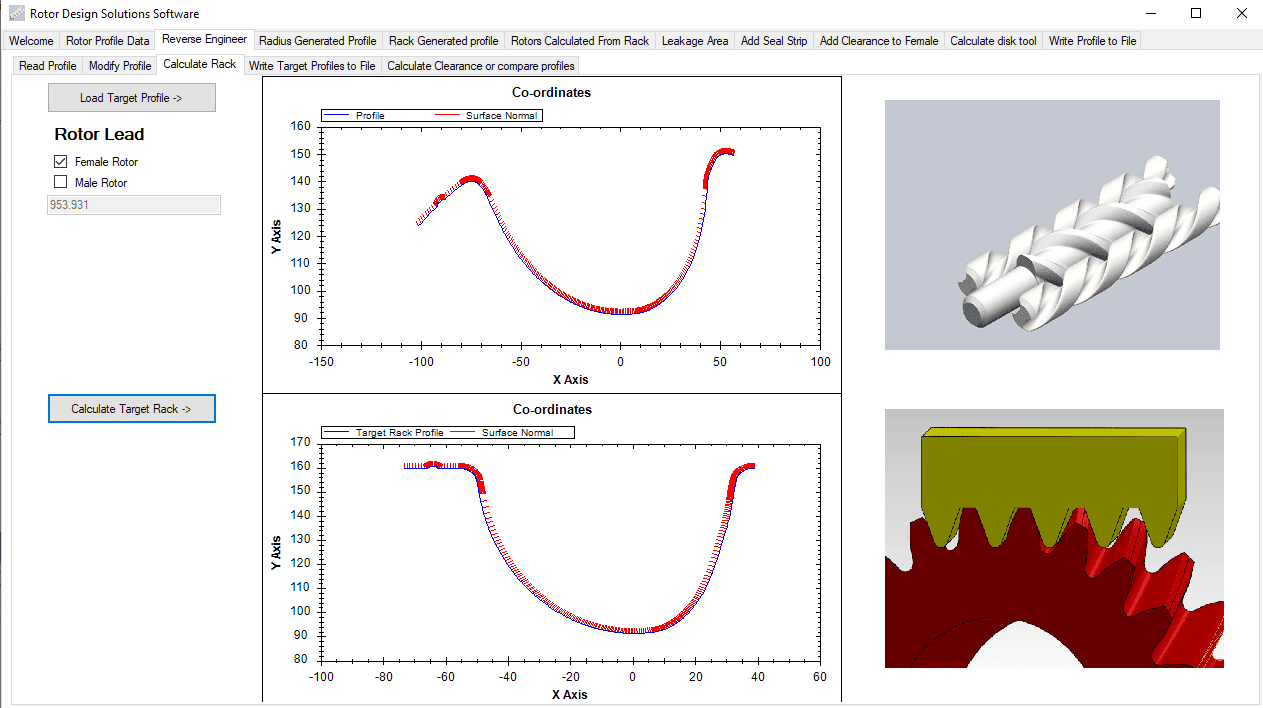

That’s where Rotor Design Solutions software comes in. Using modern, stable mathematical algorithms, our software applies an iterative process to determine the exact contact geometry between the tool and the rotor. With each pass, the algorithm refines the estimate until the result achieves near-zero error—ensuring accuracy, reliability, and repeatability.

With Rotor Design Solutions, you benefit from tooling that’s not only technically precise but optimized for real-world performance and efficiency.